4 flute solid carbide flat end mill

Flat Carbide End Mill offered allows perfect execution of the work and feature centre cutting straight flutes. With these end mills suitable for slot and form milling applications, these tools and construction material are specially designed for HSC and made available with 2/4 fluted center cutting, CNC grinding and helix angle of 30 degrees. These can be offered with different cutting & shank diameters and feature different flute and overall lengths.

4 flutes end mill

4 flutes tungsten carbide square end mill

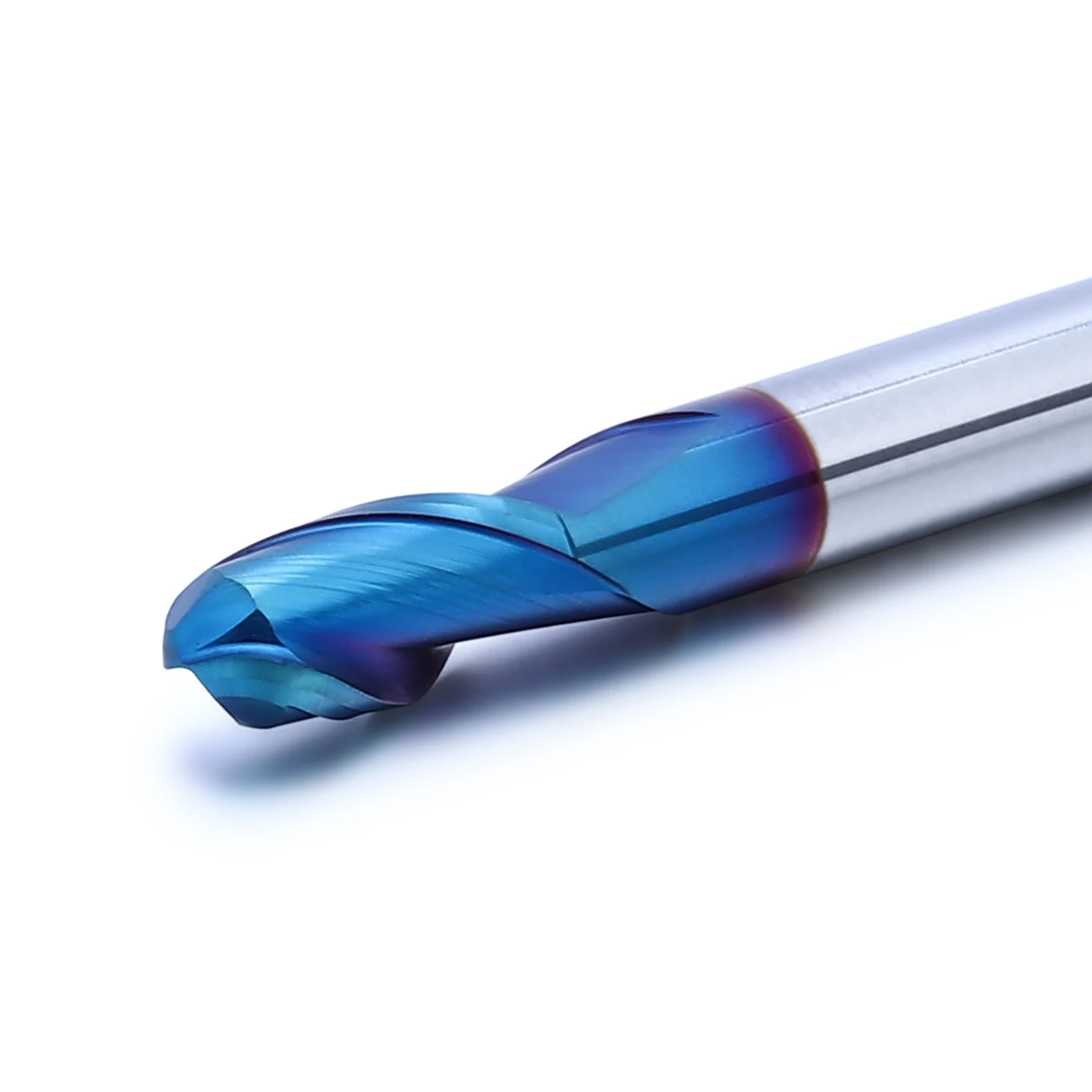

Ball Nose Solid Carbide End Mills

Advantages: Suitable for finishing,can achieve the mirror effect.

ALTIN coating from Japan, increase surface gloss,and prolonging life.

100% quality guarantee (ISO9001)Effective to avoid chatting ,allowing for oustanding milling performance

Work material: carbide steel, alloy steel, cast iron, copper, mould steel,etc.

100% original tungsten, without recycle parts. Wc90%, Co10%, more cobalt will make end mills more crisp

Long Life High Precision High Efficiency

CBN END MILLS

Cemented Carbide End Mills

Raw Material:Super material is the basis of the tools. We choose the high performance material with good wear-resistance, high hardness and high toughness.

Excellent Coating:Good coating can improve tools life and production efficiency, as well as solve the cutting problems.

Diamond End Mill Cutting Tool PCD Cutter

Raw Material:Super material is the basis of the tools. We choose the high performance material with good wear-resistance, high hardeness and high toughness.

Excellent Coating:Good coating can improve tools life and production efficiency, as well as solve the cutting problems.

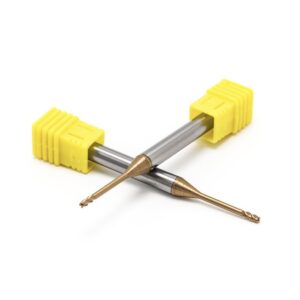

Long Neck Solid Carbide End Mill

Common end mill length is composed by two parts, cutting flute length and shank length, the cutting flute diameter is very small, below 1mm or 1-3mm, smaller than shank diameter (shank is 4mm or 3.175mm), there is one cone section length connecting the small diameter and shank, we call it neck. The long neck has a long neck as the name indicates, the long neck can avoid the interference between end mill and the workpiece, which is the very important point when mill a deep groove, so the long neck end mill is very good for deep groove milling, also named Deep Groove End Mill.

Micro Square End Mill

Micro Square End MillDouble-edge design improves rigidity and surface finish effectively.Cutting edge over the center reduces the cutting resistance.

Suitable workpiece: suitalbe for silver & Gold& Cooper& Brass &Jewelry machining, also suitable for Carbon steel, Alloy steel, pre-harden steel and harden steelSharp Edge Carbide End Mill

Solid Carbide Coated 6 Flute End Mill

Raw Material

Super material is the basis of the tools. We choose the high performance material with good wear-resistance, high hardeness and high toughness.Excellent Coating

Good coating can improve tools life and production efficiency, as well as solve the cutting problems.Solid Carbide Corner Radius End Mill

+86-139-158-49649 | sales@grandcarbidetool.com

Grand Carbide Tool © Copyright 2013. All Rights Reserved. Support by WebSun