Special Carbide End Mill

Advantages: Suitable for finishing,can achieve the mirror effect.

ALTIN coating from Japan, increase surface gloss,and prolonging life.

100% quality guarantee (ISO9001)

Work material: carbide steel, alloy steel, cast iron, copper, mould steel,etc.

100% original tungsten, without recycle parts.

Wc90%, Co10%, more cobalt will make end mill more crisp

Customised Carbide End Mill

1. Special Cutting Edge: Special cutting edge can increase the cutting ability. The lifetime of tools and machines will be longer

2. Smooth And Wide Flute: Smooth and wide flute will remove the cuttings more easily

3. Heat-resistant Coating: With highly heat-resistant HELICA coating, can be used for high-speed processing

4. Bronze Coating: Under bronze coating, any abrasion is easy to be recognized

5. High Quality Raw Material: The raw material is used of high toughness, grain-sized carbon tungsten

6. Polished Surface Treatment: With high polished surface treatment, reduce the friction coefficient could be reduced, the lathe efficiency could be improved, more production time could be saved

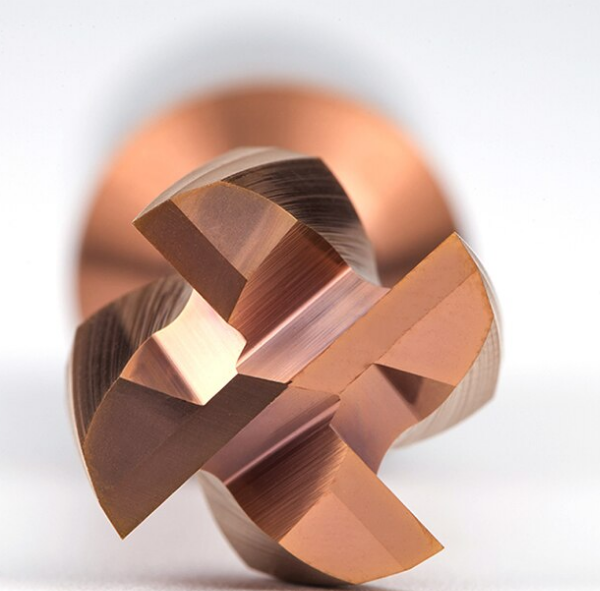

Solid Carbide Ball Nose End Mill

Raw Material:Super material is the basis of the tools. We choose the high performance material with good wear-resistance, high hardness and high toughness.

Excellent Coating:Good coating can improve tools life and production efficiency, as well as solve the cutting problems.

Solid Carbide Taps for Stainless Steel

Raw Material:Super material is the basis of the tools. We choose the high performance material with good wear-resistance, high hardness and high toughness.

Excellent Coating:Good coating can improve tools life and production efficiency, as well as solve the cutting problems.

Non-Standard Solid Carbide End Mills

Raw Material:

Super material is the basis of the tools. We choose the high performance material with good wear-resistance, high hardeness and high toughness.

Excellent Coating:

Good coating can improve tools life and production efficiency, as well as solve the cutting problems.

Non-standard Carbide Drills

Raw Material:Super material is the basis of the tools. We choose the high performance material with good wear-resistance, high hardeness and high toughness.

Excellent Coating:Good coating can improve tools life and production efficiency, as well as solve the cutting problems.

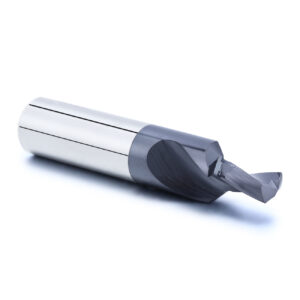

Special Carbide T-slot 6 Flute End Mill

1. Special Cutting Edge: Special cutting edge can increase the cutting ability. The lifetime of tools and machines will be longer

2. Smooth And Wide Flute: Smooth and wide flute will remove the cuttings more easily

3. Heat-resistant Coating: With highly heat-resistant HELICA coating, can be used for high-speed processing

4. Bronze Coating: Under bronze coating, any abrasion is easy to be recognized

5. High Quality Raw Material: The raw material is used of high toughness, grain-sized carbon tungsten

6. Polished Surface Treatment: With high polished surface treatment, reduce the friction coefficient could be reduced, the lathe efficiency could be improved, more production time could be saved

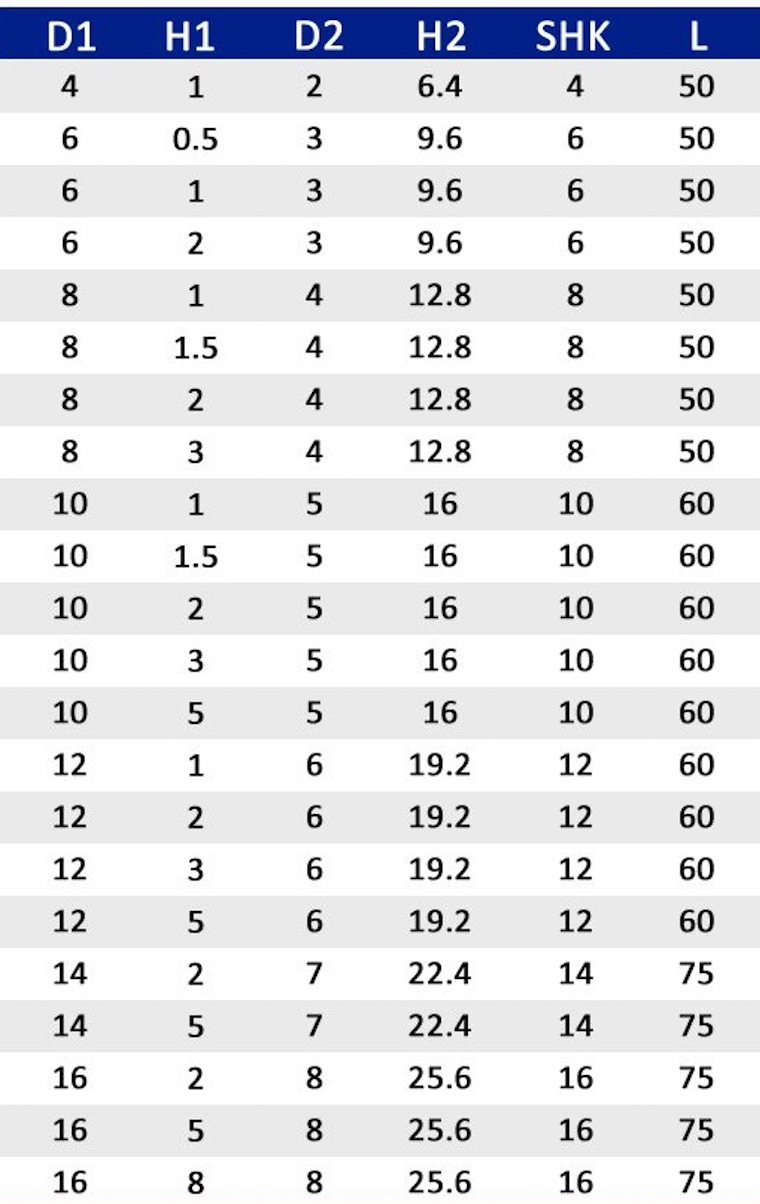

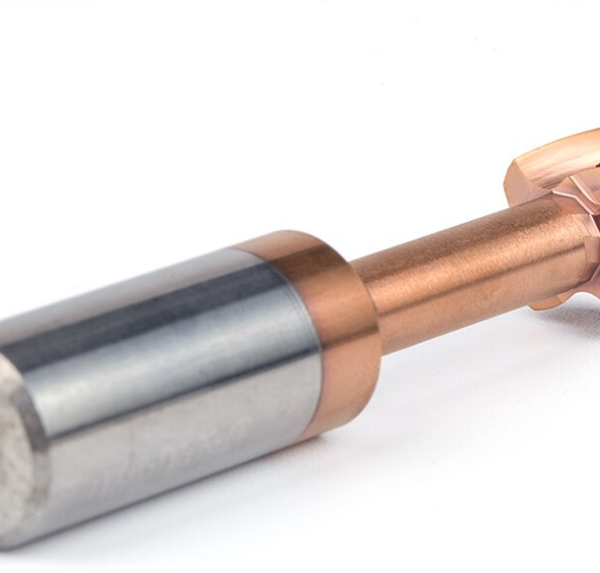

Solid Carbide Multi-step Reamer Tools

Raw Material:Super material is the basis of the tools. We choose the high performance material with good wear-resistance, high hardness and high toughness.

Excellent Coating:Good coating can improve tools life and production efficiency, as well as solve the cutting problems.